[1] is a key indicator of engine health, reflecting the sealing efficiency of pistons, valves, and rings. Low compression leads to poor performance, misfires, and even engine failure. Professional [2] provide precise diagnostics, helping you pinpoint issues before they escalate.

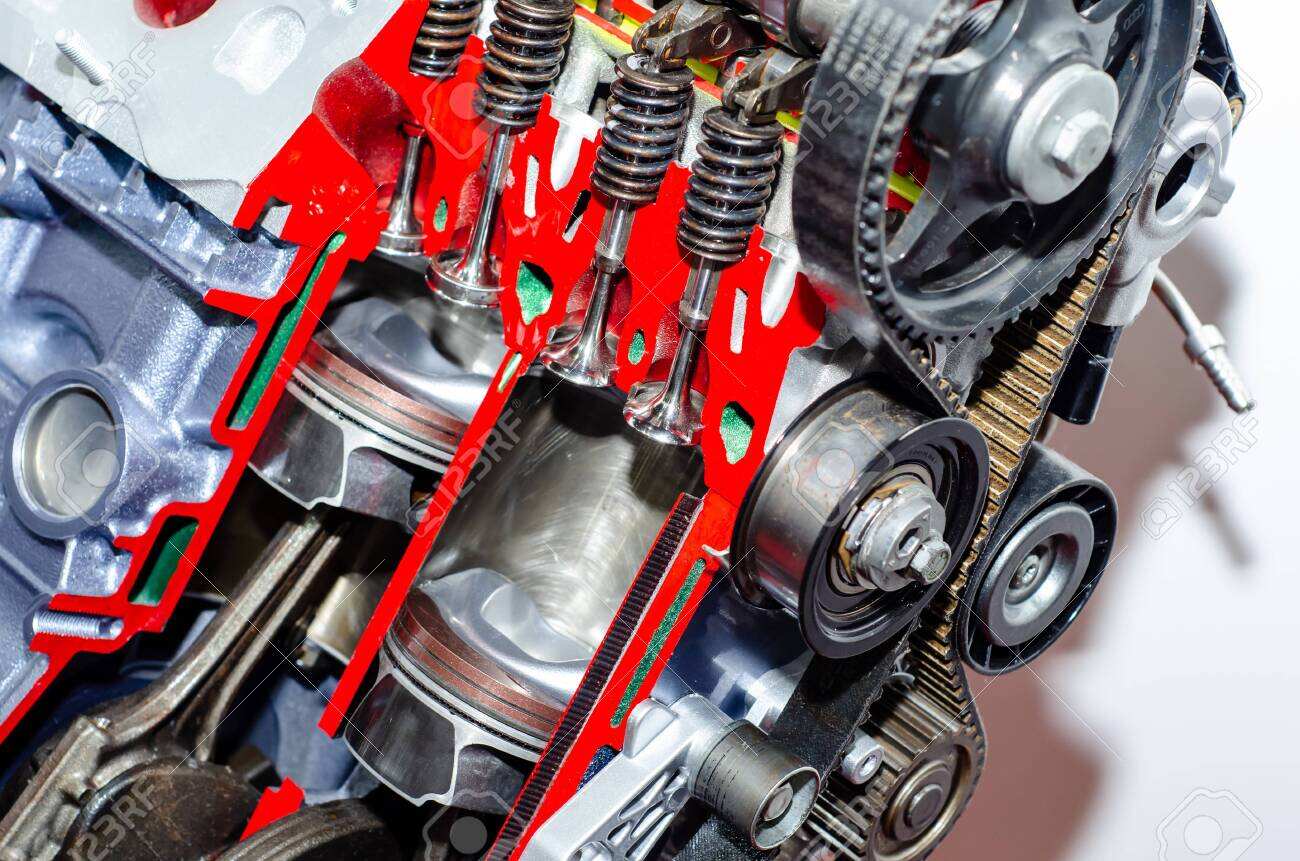

Compression measures the pressure generated in the cylinder during the compression stroke. It’s critical for efficient combustion and power delivery. Low compression can result from:

Worn piston rings.

Leaking valves or head gaskets.

Cracked cylinder walls.

Don’t wait for a breakdown—watch for these symptoms:

Loss of power or sluggish acceleration.

Misfires or rough idling.

Excessive oil consumption or blue exhaust smoke.

Hard starting or poor fuel economy.

When to Test Compression:

During routine engine diagnostics.

After overheating or major engine work.

Leak-down tools measure the percentage of air escaping from the cylinder, identifying where the problem lies. Unlike basic compression testers, they provide detailed insights into:

Piston ring wear: Air escapes into the crankcase.

Valve leaks: Air escapes through the intake or exhaust.

Head gasket issues: Air bubbles appear in the coolant.

1. Prepare the Engine

Warm up the engine to operating temperature.

Remove spark plugs and disable the fuel system.

2. Perform a Compression Test

Insert the compression gauge into the spark plug hole.

Crank the engine and record the PSI for each cylinder.

Compare readings to manufacturer specs (typically 125–200 PSI).

3. Conduct a Leak-Down Test

Connect the leak-down tester to the cylinder.

Apply compressed air and measure the percentage of leakage.

Listen and feel for air escaping to identify the source.

4. Interpret Results

<10% leakage: Healthy engine.

10–20% leakage: Moderate wear (monitor closely).

20% leakage: Significant issues requiring repair.

Testing a cold engine: Inaccurate readings due to metal contraction.

Ignoring cylinder balance: Variations 10% between cylinders indicate problems.

Skipping the leak-down test: Compression tests alone don’t reveal the root cause.

Accurate diagnostics: Pinpoint issues without guesswork.

Time savings: Faster than disassembling the engine.

Customer trust: Provide detailed reports and repair recommendations.

Cylinder compression testing is a window into your engine’s health. By using professional leak-down tools, you’ll catch problems early, save on repairs, and keep your engine running strong.

Upgrade your diagnostic toolkit with our precision leak-down testers. [Shop Now] or contact our experts for a personalized recommendation!

Q: Can I perform a compression test without tools?

A: No—specialized tools are required for accurate measurements.

Q: How often should I test compression?

A: During major service intervals or if performance issues arise.

Q: What causes uneven compression between cylinders?

A: Worn rings, valve leaks, or head gasket failure are common culprits.