[1] ensures your tires meet the road at optimal angles, maximizing grip, fuel efficiency, and tire lifespan. Misaligned wheels cause uneven wear, poor handling, and even safety risks. [2] take the guesswork out of adjustments, delivering precision that traditional methods can’t match.

Wheel alignment involves adjusting three key angles to match manufacturer specifications:

Camber: The inward/outward tilt of the tire.

Toe: The direction tires point relative to the vehicle’s centerline.

Caster: The forward/backward tilt of the steering axis.

Ignoring alignment issues costs you money and safety. Watch for these red flags:

Uneven tire wear (e.g., feathering on edges).

Vehicle pulling left or right on straight roads.

Off-center steering wheel when driving straight.

Vibrations or wobbling at high speeds.

When to Check Alignment:

After hitting potholes or curbs.

Every 6,000 miles or during tire rotations.

Laser alignment systems project beams onto sensors mounted to the wheels, measuring angles with micron-level accuracy. Unlike manual gauges, lasers provide real-time data and adjust recommendations, eliminating human error.

Key Advantages Over Traditional Methods:

Instant feedback: Adjustments are tracked live.

Compatibility: Works with all vehicle types, including EVs and trucks.

Comprehensive reports: Printouts show before/after results for customer transparency.

1. Prepare the Vehicle

Park on a level alignment rack and inflate tires to recommended PSI.

Mount laser sensors to all four wheels.

2. Calibrate the System

Input vehicle make, model, and year for OEM specs.

Ensure sensors are level and secure.

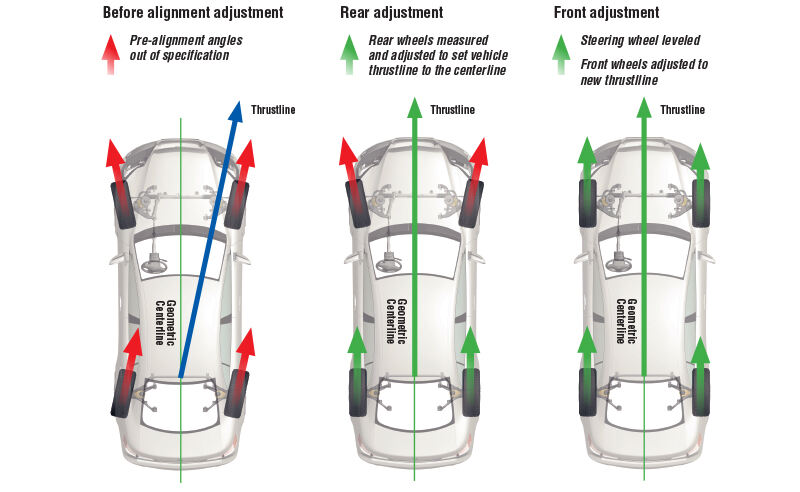

3. Measure Current Angles

Rotate wheels and let the system analyze camber, toe, and caster.

Identify deviations from factory settings.

4. Adjust Components

Loosen control arm bolts or tie rods.

Use laser-guided prompts to shift components until angles turn green (in spec).

5. Verify and Finalize

Recheck angles after tightening bolts.

Print a report for the customer and road-test the vehicle.

Skipping tire pressure checks: Uneven pressure skews measurements.

Ignoring suspension wear: Worn bushings or ball joints prevent accurate adjustments.

Rushing calibration: Sensors must be perfectly leveled for reliable data.

Save time: Complete alignments 30% faster than manual methods.

Boost customer trust: Professional reports prove your work’s quality.

Reduce comebacks: Precision adjustments prevent repeat issues.

Proper wheel alignment isn’t a luxury—it’s a necessity for safety and performance. Laser alignment systems empower technicians to deliver flawless results, keeping customers loyal and vehicles running true.

Upgrade your shop with state-of-the-art laser alignment technology. [Explore Our Systems] or contact our experts for a personalized demo!

Q: How often should wheel alignment be checked?

A: Annually or every 12,000 miles, and after any impact or suspension work.

Q: Can I align my own wheels at home?

A: Laser systems require training and specialized tools—leave it to professionals.

Q: Does alignment affect electric vehicles differently?

A: Yes, EVs’ heavier batteries demand precise alignment to avoid accelerated tire wear.

By mastering laser alignment, you’ll turn frustrated drivers into loyal customers—one perfectly aligned wheel at a time. 🚗✨🔧