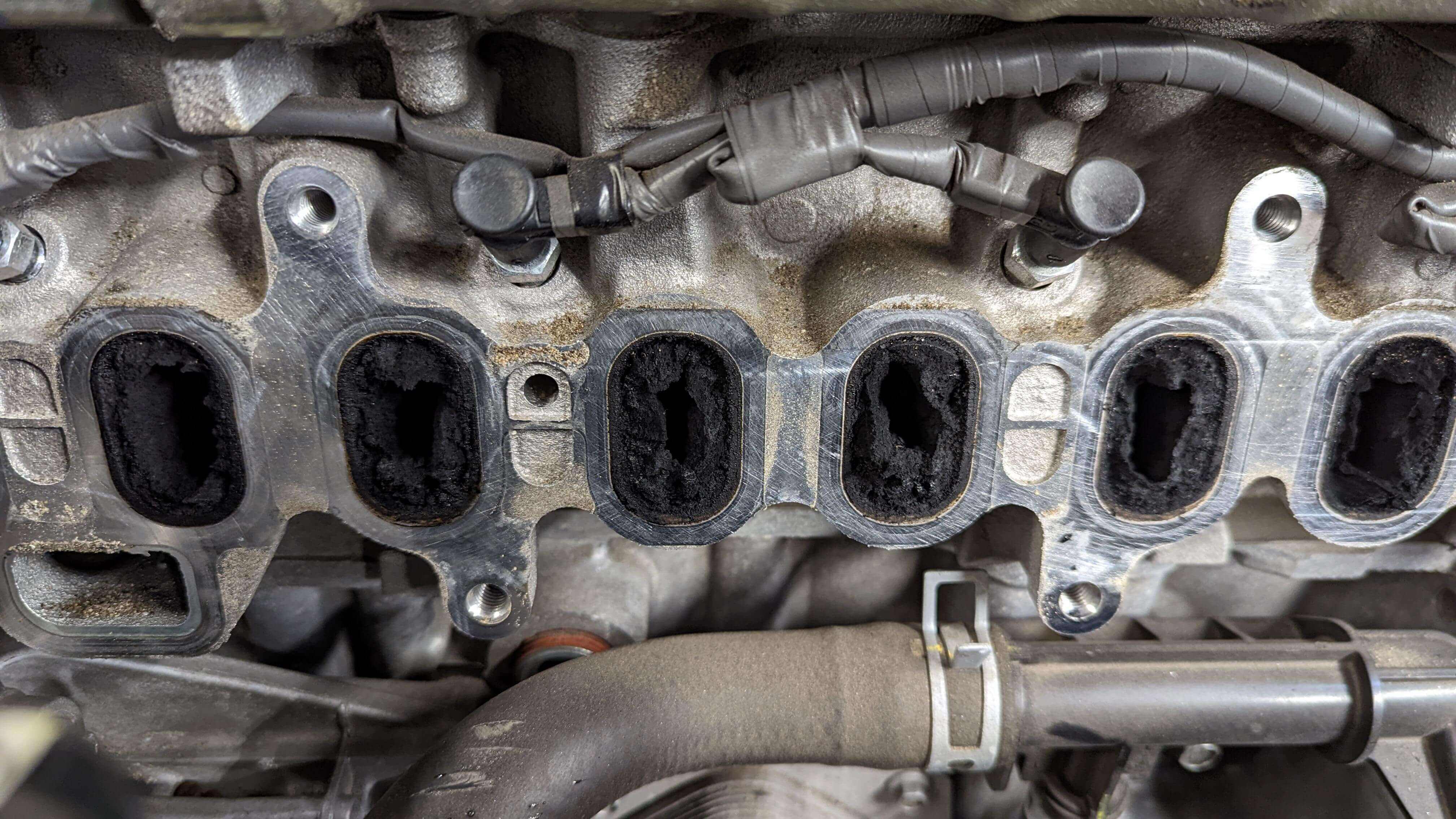

[1] deliver fuel directly into the combustion chamber, improving efficiency and power. However, unlike traditional port injection, DI systems don’t wash fuel over the intake valves. Over time, this leads to stubborn carbon deposits that rob your engine of performance, causing: Reduced horsepower and acceleration. Rough idling or misfires. Poor fuel economy. Increased emissions.

In DI engines, fuel bypasses the intake valves, leaving no detergent action to clean them. Combined with oil vapors from the PCV system, carbon accumulates on:

Intake valves: Restricting airflow.

Fuel injectors: Causing uneven spray patterns.

Combustion chambers: Creating hot spots and pre-ignition.

Traditional fuel additives can’t reach these areas, making high-pressure cleaning tools essential.

Don’t wait for a check engine light—watch for these warning signs:

Loss of power during acceleration.

Engine knocking or pinging sounds.

Increased exhaust smoke (black or gray).

Failed emissions tests.

When to Clean:

Every 30,000–50,000 miles.

After persistent drivability issues.

High-pressure cleaning systems blast carbon deposits using specialized solvents and pressurized air. Unlike additives, these tools physically scrub critical areas:

Intake valves: Solvent is injected through the intake manifold.

Fuel injectors: Ultrasonic cleaning restores spray patterns.

Combustion chambers: Decarbonizing agents dissolve buildup.

1. Prepare the Engine

Warm up the engine to operating temperature.

Disconnect the fuel pump fuse to depressurize the system.

2. Clean Intake Valves

Connect the high-pressure tool to the intake manifold.

Inject a carbon solvent and let it soak for 10–15 minutes.

Scrub valves using rotating brushes or pressurized air.

3. Clean Fuel Injectors

Remove injectors and place them in an ultrasonic cleaner.

Test spray patterns post-cleaning (replace if clogged).

4. Decarbonize Combustion Chambers

Introduce a decarbonizing agent through the spark plug holes.

Let it soak overnight, then crank the engine to expel residue.

5. Reassemble and Test

Reinstall components and reconnect the fuel system.

Perform a test drive to verify restored performance.

Skipping valve cleaning: Focus on injectors alone won’t fix airflow issues.

Using low-quality solvents: Can damage sensors or leave residue.

Ignoring manufacturer guidelines: Over-scrubbing valves risks surface damage.

Precision: Target deposits without disassembling the engine.

Efficiency: Complete cleaning in 1–2 hours vs. days of labor.

Long-term savings: Prevent costly repairs like turbocharger failure.

Carbon buildup in DI engines is inevitable, but not irreversible. With high-pressure cleaning tools, you’ll restore horsepower, improve fuel economy, and extend your engine’s lifespan—no tear-down required.

Upgrade your shop with our industrial-grade DI cleaning systems. [Shop Now] or contact our team for a customized solution!

Q: Can I clean DI systems without specialized tools?

A: No—walnut blasting or chemical soaks alone won’t fully remove hardened carbon.

Q: How long do cleaning results last?

A: 20,000–30,000 miles, depending on driving habits and maintenance.

Q: Will cleaning void my warranty?

A: No, if done using OEM-approved methods and fluids.

By tackling carbon buildup head-on, you’ll keep your direct injection engine running like new—smooth, powerful, and efficient. 🚗💨🔧