Valve guides ensure valves move smoothly while sealing combustion gases and preventing oil from leaking into the combustion chamber. When guides wear out, they allow oil to seep past the valve stems, leading to excessive oil consumption, blue exhaust smoke, and carbon buildup on spark plugs. Traditional repair methods like guide replacement are costly and time-consuming—but HTL’s diamond-coated micro-adjustable honing kits restore worn guides to factory precision, eliminating oil burn and extending engine life.

Valve guides are subjected to constant friction, heat, and lateral forces. Over time, this wear creates excessive clearance between the guide and valve stem, causing:

Oil migration: Oil slips past the valve stem seals into the combustion chamber.

Valve misalignment: Worn guides let valves wobble, accelerating seat wear.

Reduced compression: Poor sealing lowers engine efficiency.

Common Causes of Wear:

Lack of lubrication (faulty seals or low-quality oil).

High-mileage engines (natural wear over 150,000+ miles).

Aggressive driving (sustained high RPMs).

HTL’s tools are engineered to solve guide wear without costly replacements:

Diamond abrasives: Cut hardened steel or bronze guides without clogging.

Micro-adjustable mandrels: Fine-tune bore diameter in 0.001 mm increments.

Self-centering design: Maintains perfect alignment during honing.

Coolant integration: Prevents overheating and preserves guide integrity.

1. Inspect and Measure

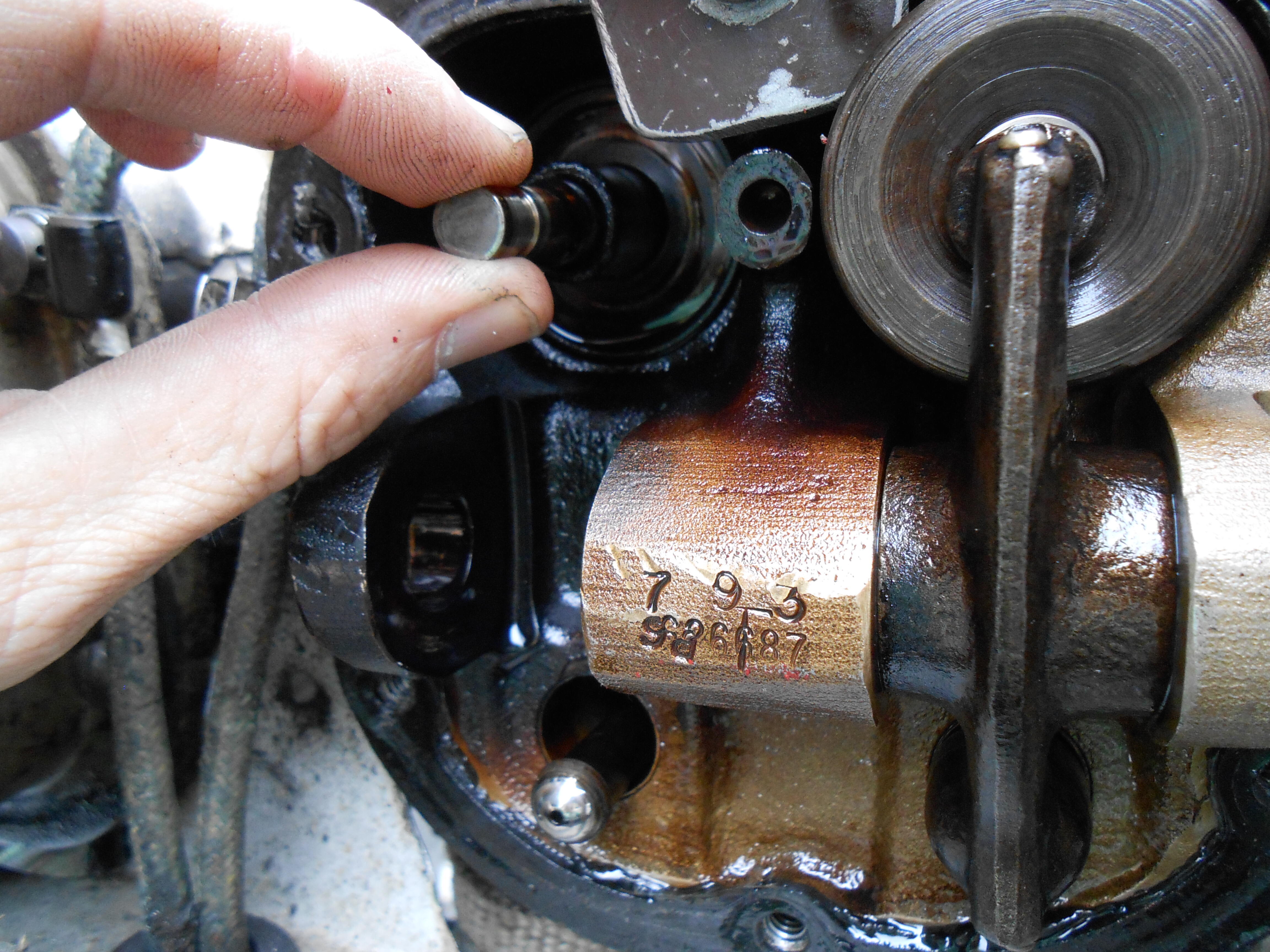

Remove the cylinder head and valves.

Use a dial bore gauge to measure guide clearance (max tolerance: 0.08–0.12 mm for intake, 0.10–0.15 mm for exhaust).

2. Select the Honing Mandrel

Choose a mandrel size based on the target bore diameter (e.g., 6.0 mm for a 5.98 mm worn guide).

3. Hone the Guide Bore

Insert the diamond-coated mandrel into the guide.

Run the honing tool at 300–500 RPM with honing oil, moving it in and out to create crosshatch patterns.

Check progress every 10 seconds with a micrometer.

4. Verify Alignment

Reinstall the valve and check for smooth rotation without binding.

Use a runout gauge to ensure valve stem deviation ≤0.03 mm.

5. Reassemble and Test

Install new valve stem seals.

Perform a vacuum test to confirm no oil leakage.

| Factor | Guide Replacement | HTL Honing |

|---|---|---|

| Labor Time | 4–6 hours (press-fit + reaming) | 1–2 hours (in-place repair) |

| Cost per Cylinder | 150 (parts + labor) | 40 (tool usage) |

| Durability | 100,000–150,000 miles | 100,000–150,000 miles (equivalent) |

| Skill Required | Advanced (risk of cracking heads) | Moderate (guided process) |

Over-honing: Exceeding OEM clearance limits worsens oil consumption.

Skipping crosshatching: Smooth bores trap oil, increasing leakage.

Ignoring valve seals: Worn seals negate honing benefits.

A repair shop faced a Toyota Camry burning 1 quart of oil every 500 miles. Diagnosis revealed worn exhaust guides. Using HTL’s honing kit:

Oil consumption dropped to 1 quart per 3,000 miles.

Compression improved by 15%, restoring power and fuel efficiency.

Customer saved $1,200 vs. head replacement.

Cost-effective: Save 60–80% vs. guide replacement.

Versatile: Works on steel, bronze, and powdered metal guides.

Eco-friendly: Reduces waste by reusing existing guides.

Valve guide reaming isn’t just a repair—it’s a revival. HTL’s honing kits empower mechanics to eliminate oil burn, reduce emissions, and deliver lasting results without the cost of major surgery.

Upgrade your shop with HTL’s diamond-coated honing kits. [Contact Us Today] for bulk pricing or technician training!

Q: Can honing fix severely worn guides?

A: Yes, if material removal stays within 0.2 mm. Beyond that, replacement is advised.

Q: How often should guides be inspected?

A: Every 60,000 miles or if oil consumption exceeds 1 quart/1,000 miles.

Q: Does honing work on aluminum heads?

A: Yes—HTL’s tools include non-ferrous abrasives for aluminum guides.

With HTL’s precision, every honing job becomes a step toward engine longevity. 🚗🔧✨