Oil pan gaskets are the unsung heroes of engine sealing, yet improper installation leads to chronic leaks, oil loss, and engine damage. Traditional methods rely on “eyeballing” bolt alignment and inconsistent torque, causing uneven gasket compression. HTL’s laser-guided alignment jigs eliminate these flaws by ensuring perfect bolt sequencing, uniform torque distribution, and gasket integrity, turning messy repairs into flawless installations.

Even minor misalignment during oil pan installation can warp the gasket, creating gaps that oil exploits. Common pitfalls include:

Uneven bolt torque: Over-tightened bolts compress the gasket excessively, while loose bolts leave gaps.

Misaligned bolt holes: Off-angle bolts shear the gasket material.

Surface contaminants: Residual oil or debris prevent proper adhesion.

Consequences:

Oil leaks contaminating drive belts and suspension components.

Reduced oil pressure triggering engine warning lights.

Costly rework and customer dissatisfaction.

HTL’s system combines laser precision with smart feedback to revolutionize gasket sealing:

Laser Projection: Projects a real-time grid onto the oil pan and engine block, highlighting bolt hole alignment.

Torque Sequencing Guidance: Guides technicians through OEM-specific torque patterns (e.g., crisscross or spiral).

Pressure Sensors: Monitor gasket compression in real-time, alerting if uneven pressure exceeds 10%.

Adaptive Clamps: Adjust tension dynamically to prevent warping during bolt tightening.

1. Surface Preparation

Clean the oil pan and engine block mating surfaces with a solvent.

Inspect for warping (max tolerance: 0.1 mm over 300 mm length).

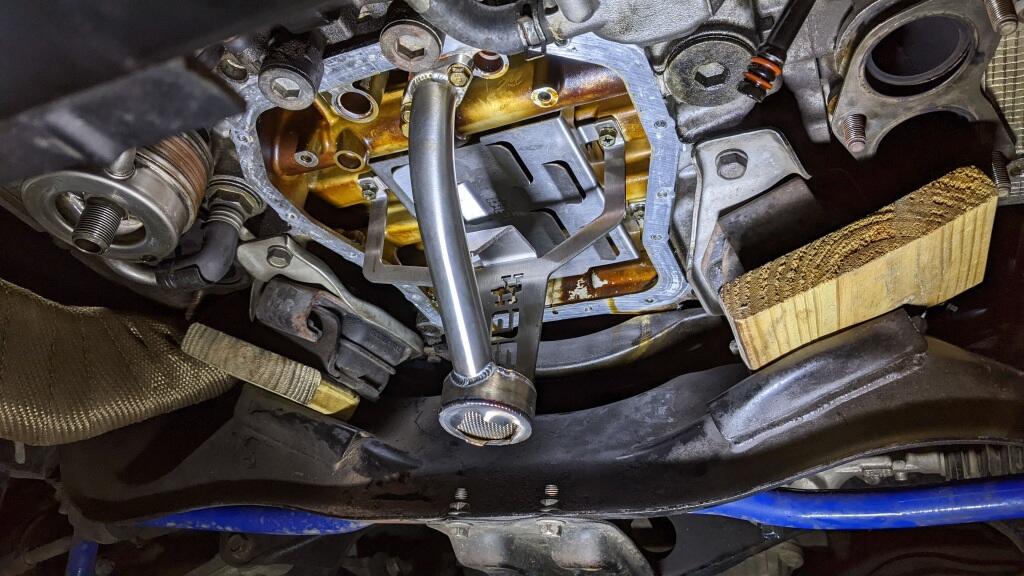

2. Position the Laser Jig

Attach HTL’s jig to the engine block, activating the laser grid.

Align the oil pan using the projected guide marks.

3. Install Gasket and Bolts

Apply a thin sealant bead (if required) and place the gasket.

Hand-tighten bolts in the sequence shown by the laser (e.g., center-out spiral).

4. Torque to Spec

Use HTL’s smart torque wrench to tighten bolts in stages (e.g., 10 Nm → 20 Nm → final torque).

The jig alerts if torque deviates ±5% from the target.

5. Post-Installation Verification

Perform a pressure test (0.5 bar for 10 minutes) to confirm no leaks.

Scan the gasket edge with UV dye to detect micro-leaks.

| Factor | Manual Installation | HTL Laser Jigs |

|---|---|---|

| Alignment Accuracy | ±2 mm (visual estimation) | ±0.1 mm (laser-guided) |

| Torque Consistency | ±20% (human variability) | ±3% (sensor-controlled) |

| Installation Time | 45–60 minutes (trial and error) | 20–30 minutes (guided process) |

| Leak Recurrence Rate | 25–30% (within 6 months) | <2% (field-tested data) |

Ignoring manufacturer patterns: OEM torque sequences are critical for even gasket load.

Reusing old bolts: Stretched bolts can’t maintain proper clamp force.

Skipping surface prep: Even tiny debris creates leak paths.

A logistics company faced recurring oil pan leaks in their diesel trucks, costing $15,000 monthly in repairs and downtime. After adopting HTL’s jigs:

Leak recurrence dropped to 1% across 200 vehicles.

Labor time per repair decreased by 65%, saving $8,000/month.

Warranty claims reduced by 90%, boosting customer trust.

Eliminate comebacks: Leak-free repairs enhance shop reputation.

Train faster: Intuitive laser guides reduce technician learning curves.

Versatility: Compatible with aluminum, steel, and composite pans.

Oil pan leaks are no longer inevitable. HTL’s laser-guided jigs transform gasket installation from a chore into a science, ensuring engines stay dry and customers stay happy.

Upgrade your shop with HTL’s laser alignment technology. [Request a Demo] or download our free torque sequence guides!

Q: Can the jig handle curved or irregular oil pans?

A: Yes—HTL’s adjustable arms accommodate most pan geometries.

Q: How often should the laser be calibrated?

A: Annually or after 500 installations (whichever comes first).

Q: Does sealant type affect performance?

A: HTL’s system works with RTV, cork, rubber, and OEM gaskets.

With HTL’s precision, every oil pan installation becomes a guarantee—not a gamble. 🚗🔧💧