Oil pumps are the heart of your engine’s lubrication system, ensuring critical components like bearings and camshafts stay protected. But when pump gears wear down, they create excess clearance, reducing oil pressure and starving your engine of vital lubrication. Left unchecked, this leads to overheating, accelerated wear, or even seized engines. With HTL’s gear clearance test kits, you can diagnose and recalibrate worn pumps, restoring oil pressure and preventing costly failures.

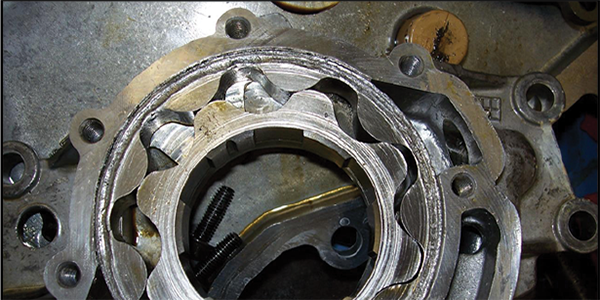

Oil pumps rely on tightly meshed gears to generate pressure. Over time, abrasion from contaminants, poor oil quality, or overheating erodes gear teeth, increasing clearance between the gears and pump housing. This allows oil to slip past instead of being forced through the engine, resulting in:

Low oil pressure warnings (dashboard alerts or gauge drops).

Ticking or knocking noises from unlubricated bearings.

Metal shavings in oil due to increased friction.

Critical Clearance Thresholds:

New gear clearance: 0.03–0.08 mm (varies by engine).

Wear limit: Exceeding 0.15 mm requires immediate repair.

Guessing gear clearance with feeler gauges is outdated. HTL’s kits use laser-calibrated tools to measure and adjust gear meshing with surgical precision:

Digital bore gauges: Measure gear-to-housing clearance within 0.001 mm.

Adjustment shims: Fine-tune gear alignment for optimal pressure.

Wear pattern analysis strips: Identify uneven contact points.

Torque-controlled drivers: Ensure consistent bolt tension during reassembly.

1. Remove and Inspect the Oil Pump

Drain oil and disconnect the pump from the engine block.

Clean gears and housing with solvent to remove sludge.

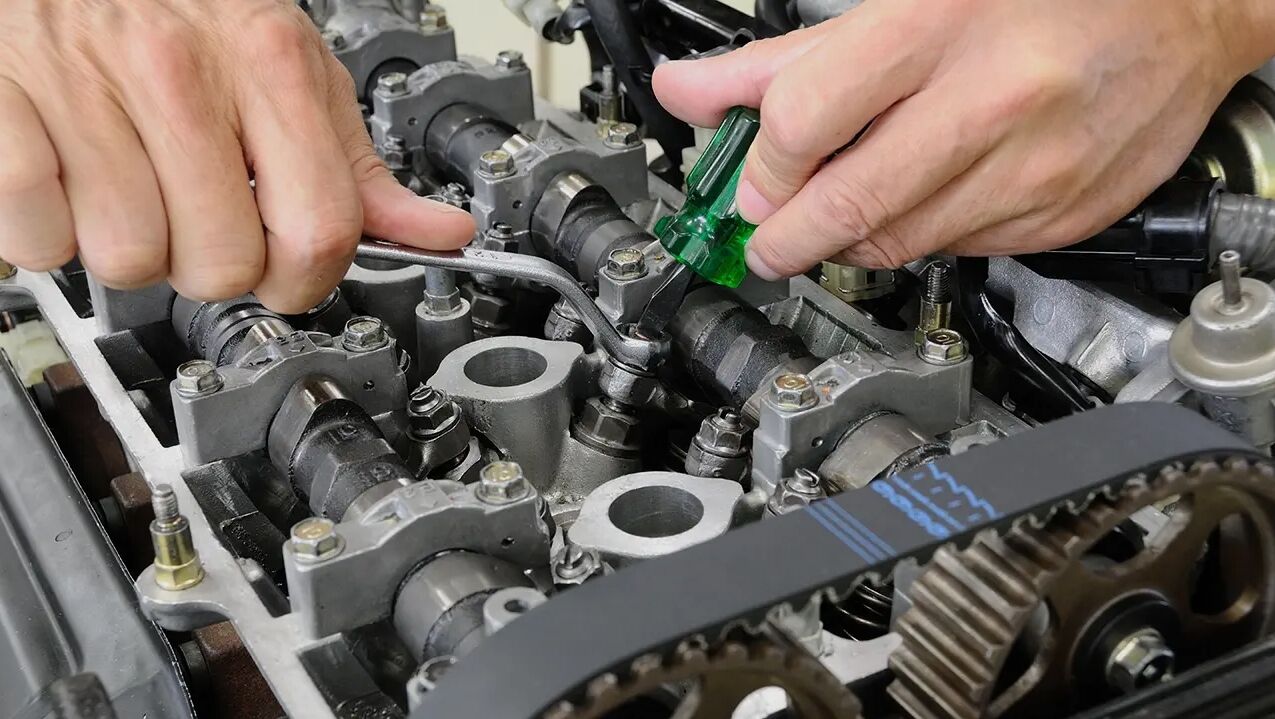

2. Measure Gear Clearance

Place HTL’s digital bore gauge between gear teeth and housing.

Rotate gears to check clearance at multiple points.

3. Analyze Wear Patterns

Apply HTL’s contact strips to gear surfaces.

Uneven wear indicates misalignment or housing warping.

4. Recalibrate the Pump

Install adjustment shims to reduce excess clearance.

Reassemble gears and torque bolts to OEM specs (e.g., 10–15 Nm).

5. Test Under Load

Prime the pump with oil and use a pressure gauge to verify output.

Target pressure: 40–60 PSI at idle (varies by engine).

Ignoring housing wear: Replacing gears without addressing the housing is futile.

Over-shimming: Excessive shims bind gears, causing rapid wear.

Skipping post-repair tests: Verify pressure at both idle and high RPM.

Accuracy: Eliminate human error in clearance measurement.

Speed: Diagnose and fix in half the time of manual methods.

Longevity: Proper calibration extends pump life by 30–50%.

Equip your shop with HTL’s precision calibration kits. [Contact Us Today] for bulk pricing or technical support!

Q: Can I reuse old shims during calibration?

A: No—always use new shims to ensure accurate adjustments.

Q: How often should oil pumps be inspected?

A: Every 60,000 miles or during major engine services.

Q: What if clearance is within spec but pressure remains low?

A: Check for clogged oil passages or a failing pressure relief valve.

By mastering oil pump calibration, you’ll transform worn-out engines into smooth, reliable powerplants—one precise adjustment at a time. 🛠️🚗💧