Hydraulic lifters are supposed to keep your engine quiet by adjusting valve clearance automatically. But when air bubbles get trapped inside them, that annoying ticking sound starts. Left unchecked, it can lead to poor valve timing, reduced power, and even accelerated wear. The good news? With the right tools—like Hangzhou Hongtu’s pressure priming kits—you can silence that tick and restore smooth engine performance.

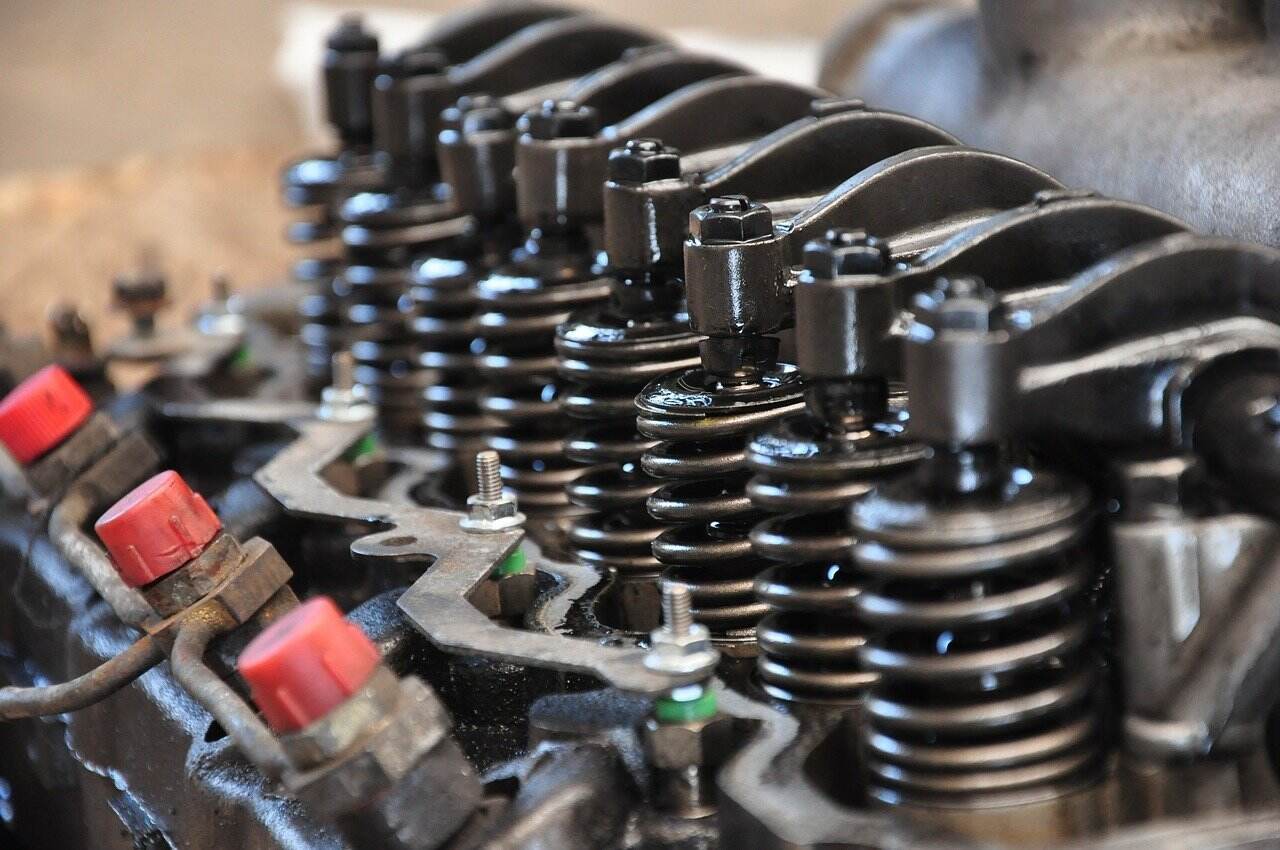

Hydraulic lifters rely on oil pressure to function. When air bubbles enter the system (often due to low oil, worn components, or improper bleeding), they compress instead of transferring force to the valves. This creates that dreaded ticking noise and throws off your engine’s rhythm.

Common Culprits:

Old or contaminated oil (sludgy oil traps air).

Worn lifter seals or weak oil pumps.

Incorrect bleeding after engine repairs.

Traditional methods like manual bleeding or oil additives are hit-or-miss. Hangzhou Hongtu’s pressurized priming tools tackle the issue head-on by:

Forcing oil through the lifter to purge trapped air.

Mimicking engine oil pressure to reseat components.

Saving time compared to trial-and-error approaches.

Why HTL’s Tools Stand Out:

Ergonomic design for tight engine bays.

Adjustable pressure settings to match OEM specs.

Durable construction for repeated use.

1. Prep the Engine

Let the engine cool completely.

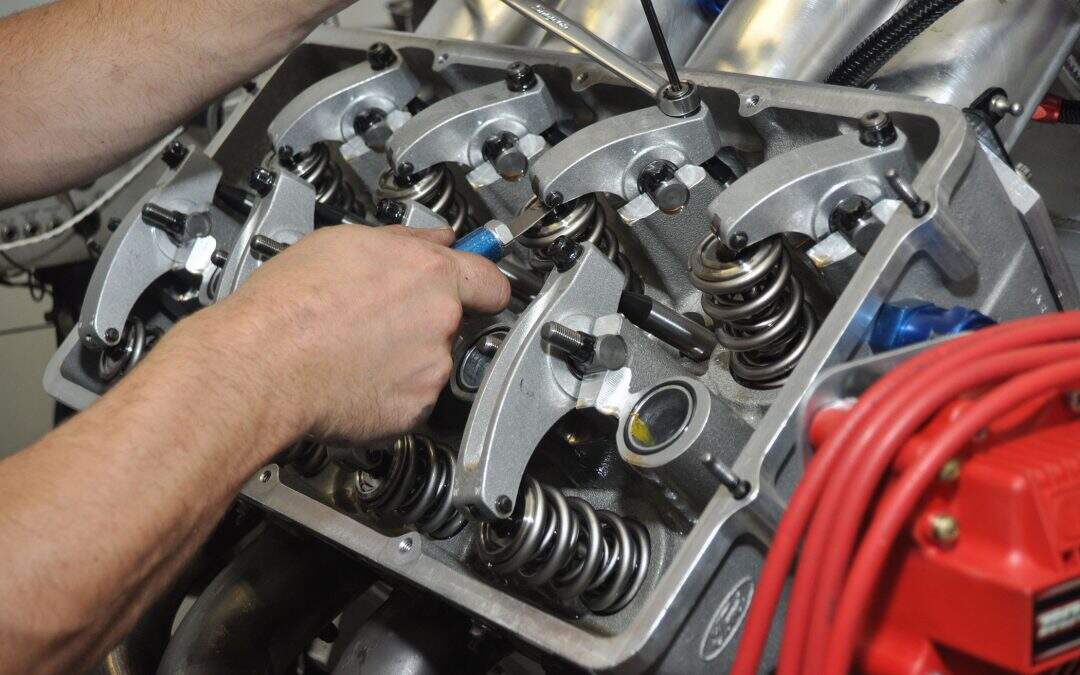

Remove the valve cover to access the lifters.

2. Connect the Priming Tool

Attach the tool’s nozzle to the lifter oil port.

Set the pressure to match your vehicle’s specs (typically 30–60 PSI).

3. Purge Air Bubbles

Slowly pump oil through the lifter until bubbles stop escaping.

Listen for the ticking noise to fade as air is expelled.

4. Test and Repeat

Reassemble the valve cover and start the engine.

If ticking persists, repeat the process for stubborn lifters.

Skipping the oil change: Dirty oil will reintroduce air.

Over-pressurizing: Can damage lifter seals.

Ignoring root causes: Fix oil leaks or pump issues first.

Faster results: Silence ticks in minutes, not hours.

Precision control: Avoid guesswork with adjustable pressure.

Long-term savings: Extend lifter lifespan and avoid replacements.

Ready to silence your engine? [Shop HTL’s priming kits here] or contact our team for personalized advice!

Q: Can I bleed lifters without special tools?

A: You can try manual methods, but they’re less effective. Pressure tools guarantee results.

Q: How often should lifters be bled?

A: Only when noise occurs or after major engine work. Regular oil changes prevent most issues.

Q: Will this fix lifter noise permanently?

A: Yes, if air bubbles are the cause. Address underlying issues (e.g., oil leaks) to prevent recurrence.