Clutch chatter—a rhythmic shaking or vibration during engagement—often stems from irregularities on the flywheel’s friction surface. These imperfections, such as warping, scoring, or thermal hotspots, disrupt the even contact between the flywheel and clutch disc, causing uneven pressure distribution and vibrations. Common causes include:

Thermal stress: Repeated clutch slipping generates heat, warping the flywheel surface.

Abrasive wear: Contaminants like dirt or metal particles embed into the friction surface, creating grooves.

Improper machining: Subpar resurfacing techniques leave micro-roughness or uneven material removal.

HTL’s diamond cutting tools address these issues by restoring the flywheel to a mirror-like finish, ensuring uniform clutch engagement and eliminating chatter.

Traditional flywheel resurfacing relies on grinding stones or manual lathes, which have significant limitations:

| Factor | Traditional Methods | HTL Diamond Cutting |

|---|---|---|

| Surface Finish (Ra) | 1.6–3.2 µm (prone to micro-grooves) | ≤0.4 µm (ultra-smooth, ideal for clutch discs) |

| Precision | ±0.1 mm (risk of uneven surfaces) | ±0.01 mm (laser-guided accuracy) |

| Speed | 2–3 hours per flywheel | 30–45 minutes (automated process) |

| Tool Longevity | Frequent replacement due to wear | Diamond-coated tools last 10x longer |

HTL’s diamond cutting machines use adaptive toolpaths and real-time vibration damping to eliminate chatter during machining, a critical advancement over older methods.

HTL’s technology combines aerospace-grade engineering with user-friendly automation:

Surface Scanning: A 3D laser scanner maps the flywheel’s warpage and wear patterns.

Dynamic Tool Adjustment: The machine adjusts cutting depth and speed in real-time to compensate for irregularities.

Vibration Control: Active damping systems suppress machining vibrations, preventing secondary surface damage.

Final Polishing: A diamond-tipped finishing pass achieves a Ra ≤ 0.4 µm surface, critical for smooth clutch operation.

1. Inspect and Clean

Check for cracks or severe warping (max tolerance: 0.05 mm over 150 mm length).

Degrease the flywheel to remove oil and debris.

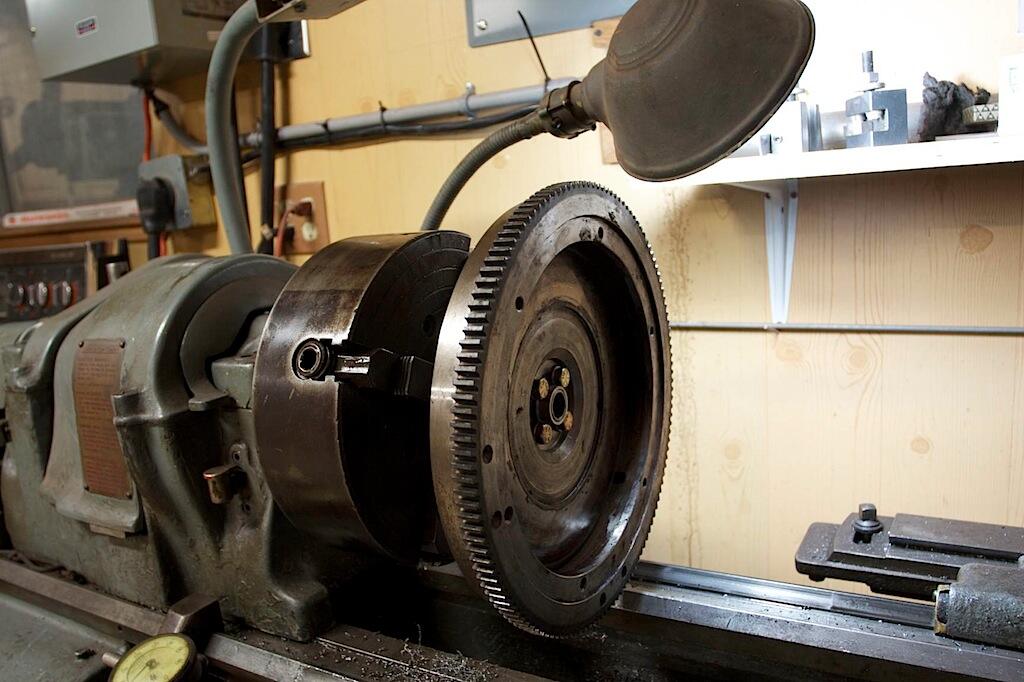

2. Mount on HTL Machine

Secure the flywheel using HTL’s vacuum clamping system to minimize flex.

3. Automated Resurfacing

The machine removes material in 0.05 mm increments, prioritizing high-wear areas.

Coolant jets prevent heat buildup, preserving metallurgical integrity.

4. Post-Machining Verification

Use a surface profilometer to confirm Ra ≤ 0.4 µm and parallelism within 0.01 mm.

5. Reassemble and Test

Install the flywheel and clutch assembly, then road-test for chatter-free operation.

A fleet maintenance workshop reported clutch chatter in 40% of their trucks after 200,000 km. After adopting HTL’s diamond cutting:

Chatter recurrence dropped to 2% within 12 months.

Clutch lifespan increased by 30% due to reduced friction surface wear.

Labor costs decreased by 50% per flywheel repair.

Material Integrity: Diamond cutting generates less heat, avoiding surface hardening.

Efficiency: Automated processes reduce human error and downtime.

Sustainability: Longer tool life and reduced waste align with eco-friendly practices.

Flywheel resurfacing isn’t just a repair—it’s a performance upgrade. HTL’s diamond cutting tools eliminate clutch chatter, extend component life, and set a new standard for precision in automotive machining.

Upgrade your workshop with HTL’s diamond cutting systems. [Contact Us] for a free consultation or demo!

Q: Can severely warped flywheels be salvaged?

A: Yes, if material removal stays within OEM limits (typically ≤1.0 mm total).

Q: How often should flywheels be resurfaced?

A: During clutch replacement or if chatter symptoms arise.

Q: Does resurfacing affect flywheel balance?

A: HTL’s machines include dynamic balancing checks to ensure ±1 g·cm tolerance.

By integrating diamond cutting technology, workshops can transform clutch repairs from a recurring cost into a competitive advantage. 🚗🔧✨