Engine blocks endure extreme thermal cycling, mechanical stress, and corrosion, leading to cracks in critical areas like cylinder walls, water jackets, or main bearing webs. Traditional welding repairs often fail due to heat distortion, residual stress, or incompatibility with cast iron/aluminum alloys. Cold metal stitching offers a heat-free, permanent solution by mechanically locking cracks with precision inserts, preserving block integrity without compromising its structure.

A cracked engine block isn’t just a leak—it’s a ticking time bomb. Left unrepaired, cracks can:

Contaminate oil: Coolant seeping into oil galleries causes lubrication failure.

Warp cylinder bores: Uneven heat distribution distorts piston alignment.

Trigger catastrophic failure: Cracks propagate under load, leading to total engine seizure.

Common Crack Locations:

Cylinder walls (near combustion chambers).

Water jacket junctions (thermal stress hotspots).

Main bearing webs (fatigue from torsional forces).

HTL’s technology combines aerospace-grade materials and mechanical interlocking to restore block strength:

Tapered Locking Keys: Machined from high-nickel alloy, these keys bridge the crack and redistribute stress.

Threaded Pins: Screwed into pre-drilled holes along the crack path, they “stitch” the fracture closed.

Sealant Integration: High-temp epoxy fills micro-gaps, ensuring coolant/oil-tight seals.

Non-Invasive Process: No heat means no risk of warping or metallurgical changes.

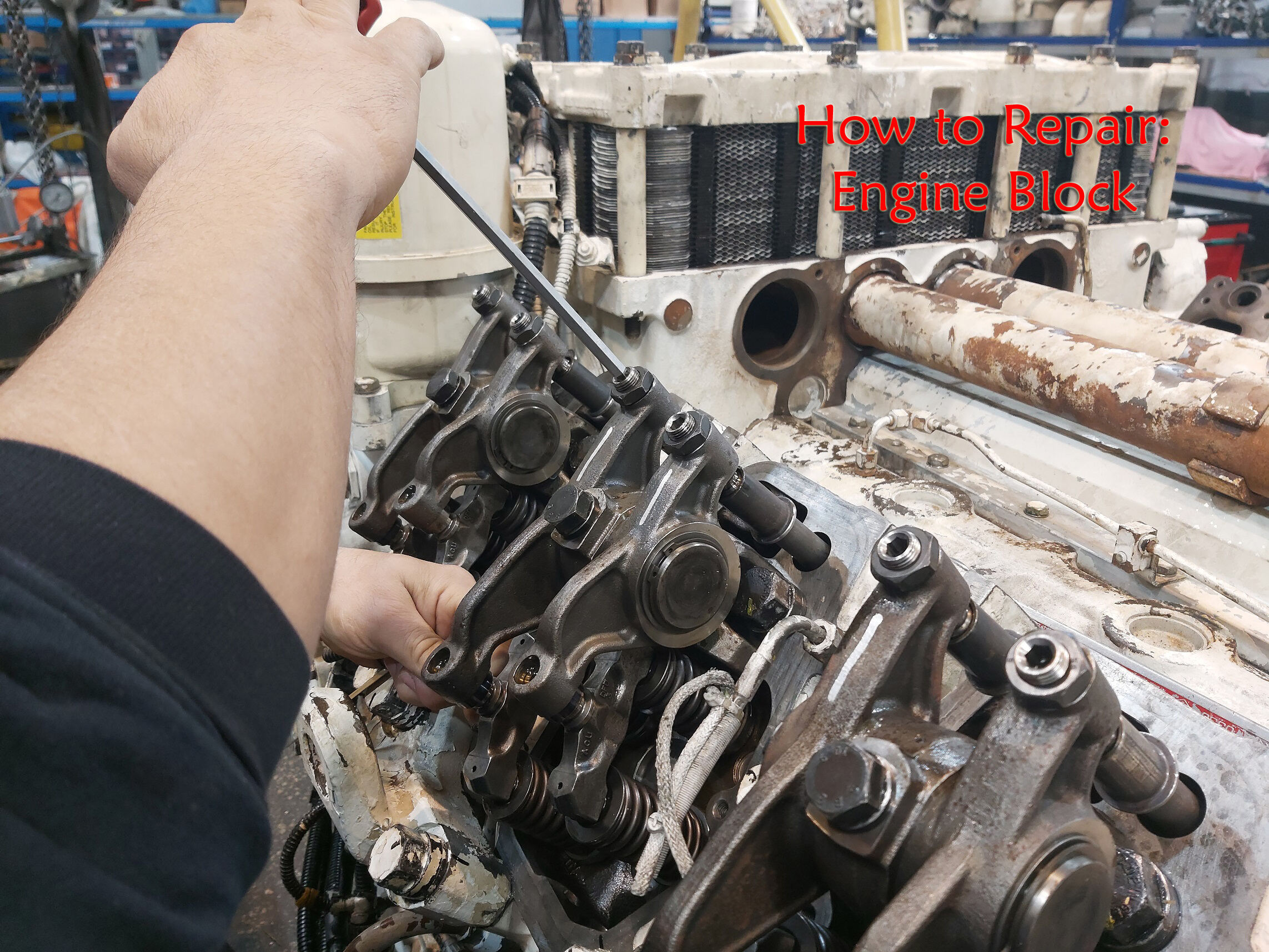

1. Crack Preparation

Clean the block thoroughly, removing oil, coolant, and debris.

Use a dye penetrant to map the crack’s full extent.

2. Drill and Tap Holes

Drill overlapping holes along the crack (3–5 mm spacing).

Tap threads for stitching pins (e.g., M6 or M8).

3. Insert Stitching Pins

Screw pins into the tapped holes, alternating sides to close the crack progressively.

Trim pins flush with the block surface.

4. Install Locking Keys

Mill slots across the crack and press in tapered keys with HTL’s hydraulic driver.

Peen the keys to expand and lock them in place.

5. Seal and Finish

Apply HTL’s high-temperature epoxy to seal residual gaps.

Machine or grind the surface to restore smoothness.

| Factor | Traditional Welding | HTL Cold Stitching |

|---|---|---|

| Heat Impact | High (risks warping/microcracks) | None (cold process) |

| Material Compatibility | Limited (cast iron/aluminum issues) | Universal (works on all alloys) |

| Repair Longevity | 1–3 years (often fails at weld seams) | 10+ years (lab-tested) |

| Skill Required | Advanced (certified welders) | Moderate (guided tooling) |

Underestimating crack length: Dye testing is critical to expose hidden damage.

Skipping pin staggering: Straight-line pin rows weaken the repair.

Ignoring sealant cure times: Rushing epoxy application causes leaks.

Salvage irreplaceable blocks: Perfect for vintage, racing, or custom engines.

Cost-effective: Repairs cost 30–50% less than block replacement.

Eco-friendly: Reduces waste by reusing OEM blocks.

Engine block cracks don’t have to mean the end. With HTL’s cold stitching kits, shops can deliver permanent, heat-free repairs that withstand the toughest conditions—preserving history and performance alike.

Equip your shop with HTL’s cold stitching technology. [Request a Sample Kit] or join our certified repair training program!

Q: Can cold stitching repair cylinder head cracks?

A: Yes—kits include adapters for heads, manifolds, and gearboxes.

Q: How deep can cracks be repaired?

A: Up to 75% of the block’s wall thickness (deeper cracks may require reinforcement).

Q: Is post-repair machining necessary?

A: Yes—surface grinding ensures proper gasket sealing.

With HTL’s cold stitching, every cracked block becomes a testament to resilience. 🚗🔧💥