The Hidden Culprit Behind Engine Vibrations: Balance Shaft Misalignment

Balance shafts are engineered to cancel out inherent [1], particularly in 4-cylinder and V6 engines. When their timing falls out of sync with the crankshaft, they amplify rather than dampen vibrations, leading to harsh cabin shakes, premature bearing wear, and driver fatigue. HTL’s [2] eliminate these issues by precisely synchronizing balance shaft rotation, restoring engine smoothness and longevity.

Balance shafts counterbalance the reciprocating forces of pistons and connecting rods. Misalignment—even by a few degrees—disrupts this harmony, causing:

Secondary vibrations: Felt as seat-of-the-pants buzzing at specific RPM ranges (e.g., 1,500–2,500 RPM).

Oil foaming: Excessive shaking aerates engine oil, reducing lubrication efficiency.

Component fatigue: Harmonic vibrations crack exhaust manifolds and loosen electrical connectors.

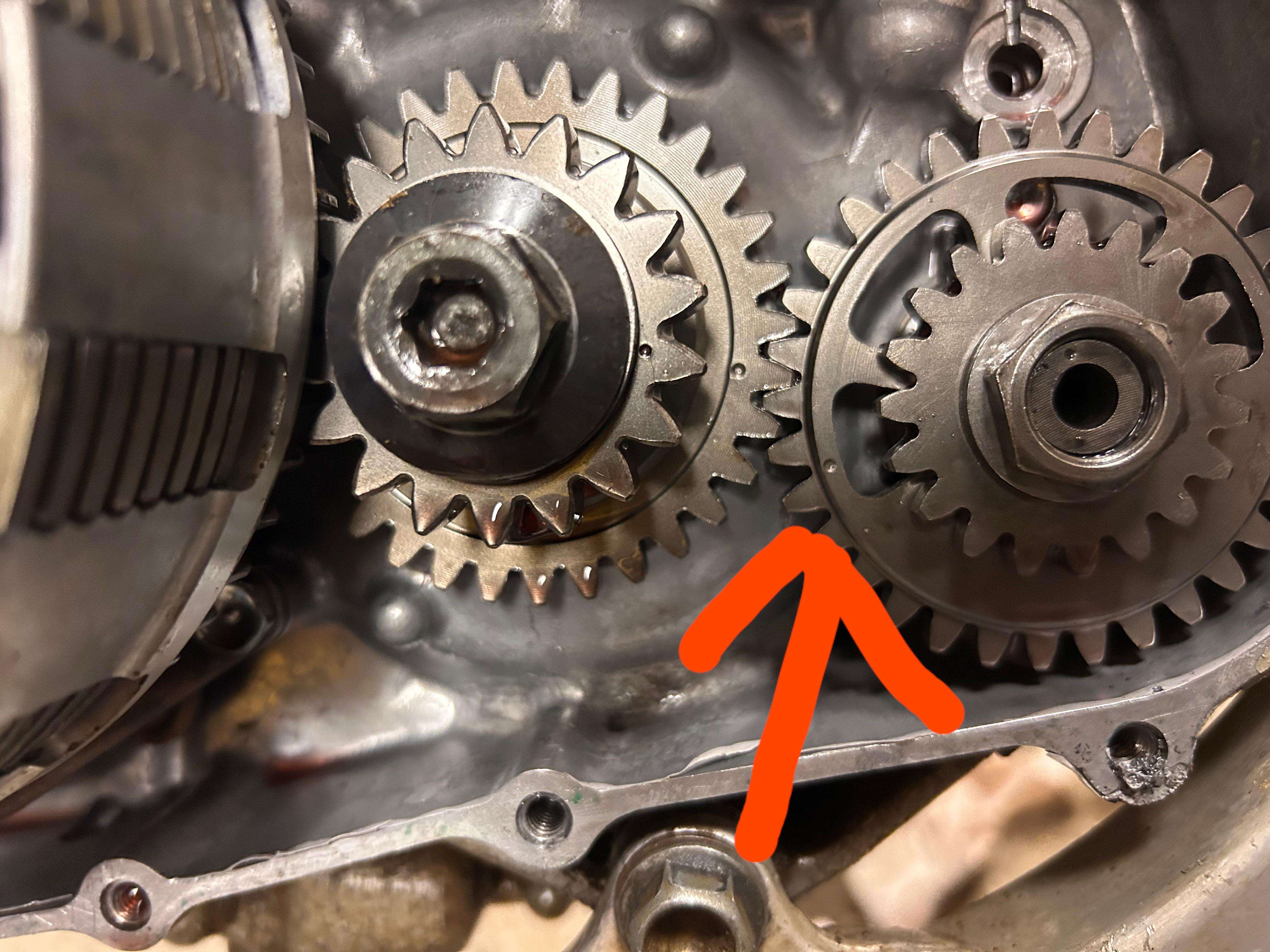

Common Causes of Misalignment:

Worn timing chains or gears.

Improper assembly during engine rebuilds.

Stretched balance shaft belts (in belt-driven systems).

HTL’s system replaces guesswork with data-driven calibration:

Laser angle encoders: Measure crankshaft and balance shaft positions to 0.1° accuracy.

Real-time phase display: Shows alignment status via Bluetooth-connected tablets.

Adjustable sprocket clamps: Fine-tune gear or sprocket positions without disassembly.

Vibration spectrum analysis: Identifies resonant frequencies pre- and post-repair.

1. Preliminary Checks

Remove timing covers and inspect chains/belts for wear.

Rotate the engine to TDC (Top Dead Center) on cylinder #1.

2. Install Phase Sensors

Attach HTL’s encoders to the crankshaft and balance shaft(s).

Sync the sensors with the diagnostic tablet.

3. Measure Current Phase Offset

Slowly rotate the engine and note the angular difference between shafts.

Acceptable tolerance: ±2° (varies by OEM).

4. Adjust Sprocket/Gear Position

Loosen the balance shaft sprocket bolts.

Use HTL’s adjustment clamp to nudge the shaft into alignment.

Tighten bolts to OEM torque specs (e.g., 50–60 Nm).

5. Validate with Vibration Analysis

Start the engine and use HTL’s software to monitor vibration levels.

Target reduction: ≥70% in secondary vibration amplitudes.

| Factor | Manual Timing | HTL Phase Tools |

|---|---|---|

| Alignment Accuracy | ±5° (prone to parallax errors) | ±0.5° (laser-guided precision) |

| Diagnostic Time | 2–3 hours (trial and error) | 30–45 minutes (automated analysis) |

| Vibration Reduction | 30–50% (partial dampening) | 70–90% (near-OEM smoothness) |

| Repeatability | Low (skill-dependent) | High (digital workflow ensures consistency) |

Ignoring chain stretch: Replace worn chains before alignment.

Over-tightening adjusters: Distorts sprockets, causing new vibrations.

Skipping post-repair tests: Verify results under load (e.g., dyno testing).

Prevent costly comebacks: Solve vibrations traditional methods miss.

Future-ready: Compatible with hybrid/electric balance systems.

Boost customer trust: Data-backed reports justify repair value.

Balance shaft timing isn’t a “set and forget” task—it’s a precision art. With HTL’s phase tools, shops can diagnose, align, and silence harmonic vibrations, delivering smoother engines and happier drivers.

Upgrade your shop with HTL’s phase alignment technology. [Schedule a Demo] or download our free vibration diagnostic checklist!

Q: Can HTL’s tools align dual balance shafts?

A: Yes—supports engines with parallel or counter-rotating shafts.

Q: How often should balance shafts be inspected?

A: Every 60,000 miles or during timing component replacements.

Q: Do electric vehicles need balance shaft alignment?

A: Yes—EV reduction gears and motor mounts also require harmonic tuning.

With HTL’s precision, every engine becomes a symphony of smooth power. 🚗🔧🎶