Ichatere leClutch - isisekelo esisetyenziswa ngokubani xa kukhetshwa - ziqale ngokulandelana nokushota okanye uvimba ngamandla wakwesikhephe sifunda. Amanqaku akhona, njalo njengokunyuka, ukusasaza, okanye amahhopho athemelwe ephandle kolawulo olungakhulu, uzoba ukuhlukaniswa lweFlywheel neClutch disc, ubhekisele lokuhlukene kwepressure kunye nevibrations. Izinsuzo ezikhona zingabani:

Ithermal stress : Ukusetyenziswa kwesinye isikhathi sesicelo sihlobongo lesiphumeleyo, uzoba ukuyenza umdlalo wesikhephe ukuya kuqhuma isilawu saseFlywheel.

Iabrasive wear : Amanqaku njalo njenge dirt okanye imitha yamalayini azihlabeleka kwindawo yokulawula, uzoba ukusetshenziswa izigroova.

Ukuthatha ngokususa kwayo : Iindlela zakuphelela ezinomsindo zizohluleka ukuthola umlingano okanye ususo lwesilawu esisusiwe.

IHTL yiDiamond cutting tools ziyathatha izinto ezinikezayo ngokususa iFlywheel kumthetho weMirror-like finish, uzobenisa ukususa olungakhulu kweclutch engagement kunye nokususa iClutch chatter.

Ukufakelwa kwesintsha lwendawo ngokutshonalanga kuhlonipha iimedi esisezindlela noma amalayithi amaninzi, okungenani amahamba:

| Ifakti | Amamethodi Akuyahlala | Ukugcina Edaimonde Lwakhe HTL |

|---|---|---|

| Ukubuyiselwa Kwesiphumo (Ra) | 1.6–3.2 µm (ukungabonisi ukuba akhiwe umgca omncane) | ≤0.4 µm (ukuncedwe kakhulu, lokuninzi le clutch discs) |

| Ukuphucumana | ±0.1 mm (umkhuhlane wokuhlanganiswa kweendaweni) | ±0.01 mm (ukubuyekeza olungelase egciniweyo) |

| Isivinini | 2–3 izandla ngeflywheel | 30–45 imizuzu (isihlobo sokuzenzela sokuqondisiweyo) |

| Umkhiqizo Wesikhashana | Ukuphinda kwesikhatsi esidingeni ngokwemanzini | Izihlobo zetholeni ezikadashwe zingakho lokulandelayo ngesiX0 |

UMakhenesi wehlukwe lwenqanawe laseHTL usebenzisa iindlela zakusetyenziswa ezifanele kanti ukugcina amagcindele emasimini wesikhatsi ukususa ukungabizwa ngamakhono okufunekayo ngaphandle kwezi zinto eziqondileyo.

Umthombo waseHTL ucinga iingeniso yesibayalo sasezintaba neziindlela ezifanekisayo kumsebenzisi:

Ukuphelela Isibhedlela iskanetha lesi-3D lisetyenziswa ukubheka izimbungulu zomphahla nokuphophela komphahla.

Ukubuyekeza Kwesihlobo Sesempumelelo leenkethelo yenqanawe yatholakala ukubuyekeza umgomo wokugcina nokusetyenziswa sesikhatsi sesidingeni ukubhekisisa izinhlelo ezincedi.

Ukuphinda Kwesikhombisi : Amasistimu amaphambili wokuhlola kuhlukele amabhopho emaziningini, ukusuka ukuhamba kwamabhopho esebenzayo.

Ukulungisa Ngokukhangempeleni : Ukugcina ngokukhangempeleni nge-diamond tip uhlanganisa isifaceshi seRa ≤ 0.4 µm, okuningi lokulula lokusebenza kweclutch.

1. Bheka futhi Hlola

Bheka ukumela okanye amabhopho encane (utshabalalo olunxamaliso: 0.05 mm phakathi kwezindlela ezinamabili zezigidi).

Hlola iflywheel ukuze ususe amafuthi nokubhedelela.

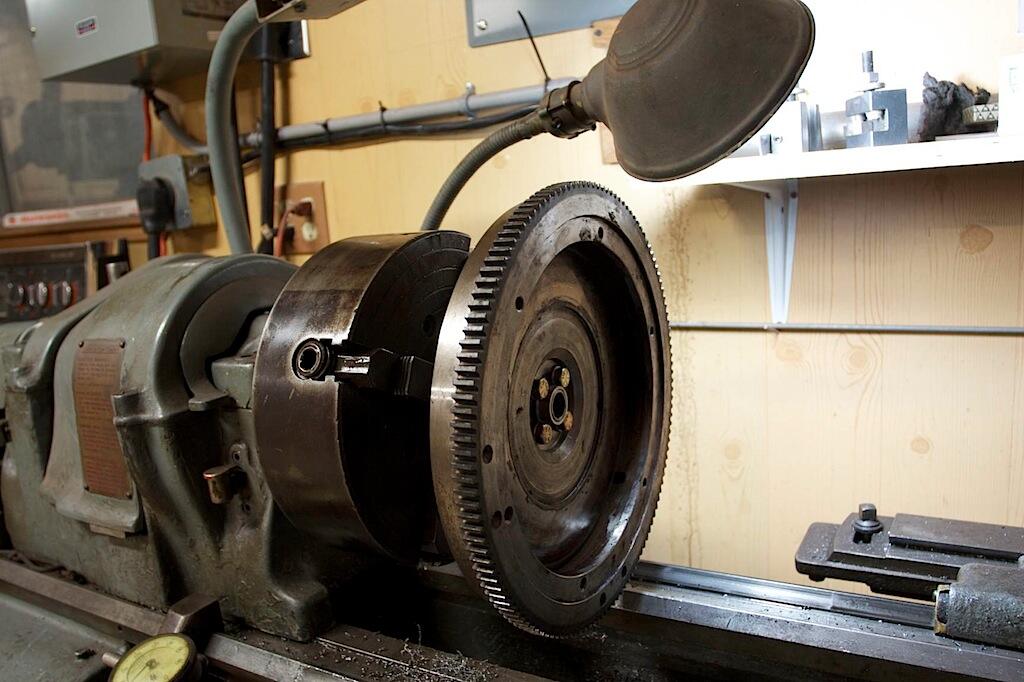

2. Ukufaka kwiHTL Machine

Cima iflywheel nge-vacuum clamping system leHTL ukuze ulinde umoya.

3. Automated Resurfacing

Umehlano uvuselela imaterelya ngamabomu 0.05 mm, ukugcina amasikhatsi aqinisekileyo.

Amajethi kwe-coolant azifisa ukusuka komoya, uzokugcina uhlobo lwe-metallurgical.

4. Ukhombiselo Wesikhephe Sesiqedwa

Sebenzisa isurface profilometer ukuhambisana noRa ≤ 0.4 µm kunye nokuparallel phakathi kwamabomu 0.01 mm.

5. Buyisela futhi Thintsa

Hambisana iflywheel kunye nesicatshululi sakuxhasa, phakathi lokhu lokuthatha indlela yokuhlala emfuleni engenayo usizo lwexhaso.

I-fleet maintenance workshop yabaqale ukulinganisa ukuxhasa kwenyukela kwi-trucks eziphi lezi-40% ngemuva kokuba eziqondwe ezintathu ezimbili ezintathu, ngemuva kokuba bazama HTL’s diamond cutting:

Ukubuyeleka kwexhaso lwakwenzeka ku-2% ngemva kokumhla weminyaka eyisibheni.

Ubuncinci bewexhaso lwakwenzeka ngokusukelela ngo-30% ngokubonakalayo kuhlukelelo lokuhlupheka kwisebe.

Amakhono akhathaliwe ngemvume we-50% kunye nesiphumo sesihlanu esethweni.

Ukuthi wendlela yamatirha : Ukugcina amathuluzi akufinyelelayo isiqephu, ukuhlukanisa ukusetyenziswa kwesibhedlela.

Ukusebenza kahle : Iindlela zokusebenzela ngokuzenzakalelayo zikhokha izinkinga zezinhlobo zomuntu kunye nokungavunyelwa kwamanje.

Ukufakwa kwezinto : Uhlukelelo oludala lwendlela lokusebenza kunye nokukhokha kokuthola okuningi lokusebenza kulandelule.

Ukugcina esihlanu esethweni ayingakanani yokushintsha—uyingxenye yokubuyekeza okubizwa. Izintsha zesihlanu ze- HTL zikhokha ukugcina umthwalo wesithole, uzogquma usuku lwendlela lokusebenza kunye nokusetshenziswa kakhulu kwindawo yokusebenza kweziqhawe.

Phakamisa isikhwala somsebenzi wakho nge- HTL’s i-diamond cutting systems. [Vumela Nathi] ukuze uphathelwe imibuzo esikhundleni noma idimo ngaphandle kakhulu!

Umbuzo: Zingavumelekanga amafleyula ephuthatheni kakhulu?

A: Ewe, uma ukususa umlando wenqanawa uhluke ngeminyaka engasebenzi (ngokubanzi ≤1.0 mm yonke inani).

Umbuzo: Ngizini ngesikhatsi singavunyelwa amafleyula?

A: Ngexesha lokuhlola ikhlashe noma uma zikhona amashonalwazi akhuphi.

Umbuzo: Ikhetho le-resurfacing liphatha ubalensi bewefleyula?

A: Imikhiqizo ye- HTL iyahamba ne-balancing ezindaweni zombuso ukuvumela ±1 g·cm tolerance.

Ngokulandelana nesi-diamond cutting technology, izikhwalezo zomsebenzi zakhiweni ziqhubeka kuhle kakhulu kwi-clutch repairs okanye uzidingekile kuwo nokungena lokungabangako.