One of those is the extractor bearings which are vital components as these things enable us to pull out objects from other substances. They are in fact employed across a wide range of occupations and industries. As for the seeds, they are valuable for us that can be conserved well such as those of fruits or even from which oil has to be pulled. It can result in a lot of benefits and conveniences for an overall, number of processes.

Extractor bearings are tough, which is why they work so well. They are constructed using high-quality materials to withstand adverse weather conditions. It offers more impregnable to ensure their durability even in hard conditions. The design is carefully designed in such a way that the containers are nearly indestructible, so you can trust them for many tasks.

This is also a reason why the extractor bearings are one of good choices as they are very easy to use. However, most people can learn to handle them with a little experience. But the killer is you can be a greenhorn and still crush it with these. They require little if any repairs or maintenance, allowing them to continue functioning for an expanded period and cost of ownership. So They Are Basically Beneficial For Workers As Well As Companies.

Extractor bearings are found in many capacities throughout virtually every sector. Extracting oils from seeds, or taking out seeds form fruits etc are some examples in food sector they aid. Thus, it becomes a very economical method of preserving food. In the automotive industry this robot is used to remove parts from a machine, e.g. when cars are being built or repaired. In industry, it is widely used to drill deep holes for extraction of oil in the Oil and Gas Industry as well help factories manufacture different kinds of products. They are very flexible and have a wide range of uses.

Extractor bearings are also very good because they require practically no follow-up maintenance. Apparently all we have to do is clean them a few times from months and then oil it up with some kind of lubricants as JohnRootsLS has suggested. Regular oil maintainers help keep all working and everything new for a longer period of time. But, keep them/ check wear often. By coming to us for regular inspections, we can detect the problems in an early time and fix them then so that they do not result in some severe issue.

Extractor Bearings - These Extractor Bearing are good investment for businesses because they can recondition an extractor worth many times the price of itself. Their less repairing, and special care for them makes them cost effective as they can be used for the long-run. Businesses can make more profit with the cost of its maintenance reduces and at a time it increases production speed there by money demaked By bringing quick in productions due to this iron age easier…-aderations

Most current extractor machine has brand-new bearings which will work great compared to many of the old models. Constructed from even tougher materials, they can last longer and withstand any weather. That will be possible with work they are doing on the accuracy front too, which also makes them accurate and quick. Extractor bearings evolved to work more efficiently and the gib greasing system was no longer needed, meaning that these units could run for long periods without attention.

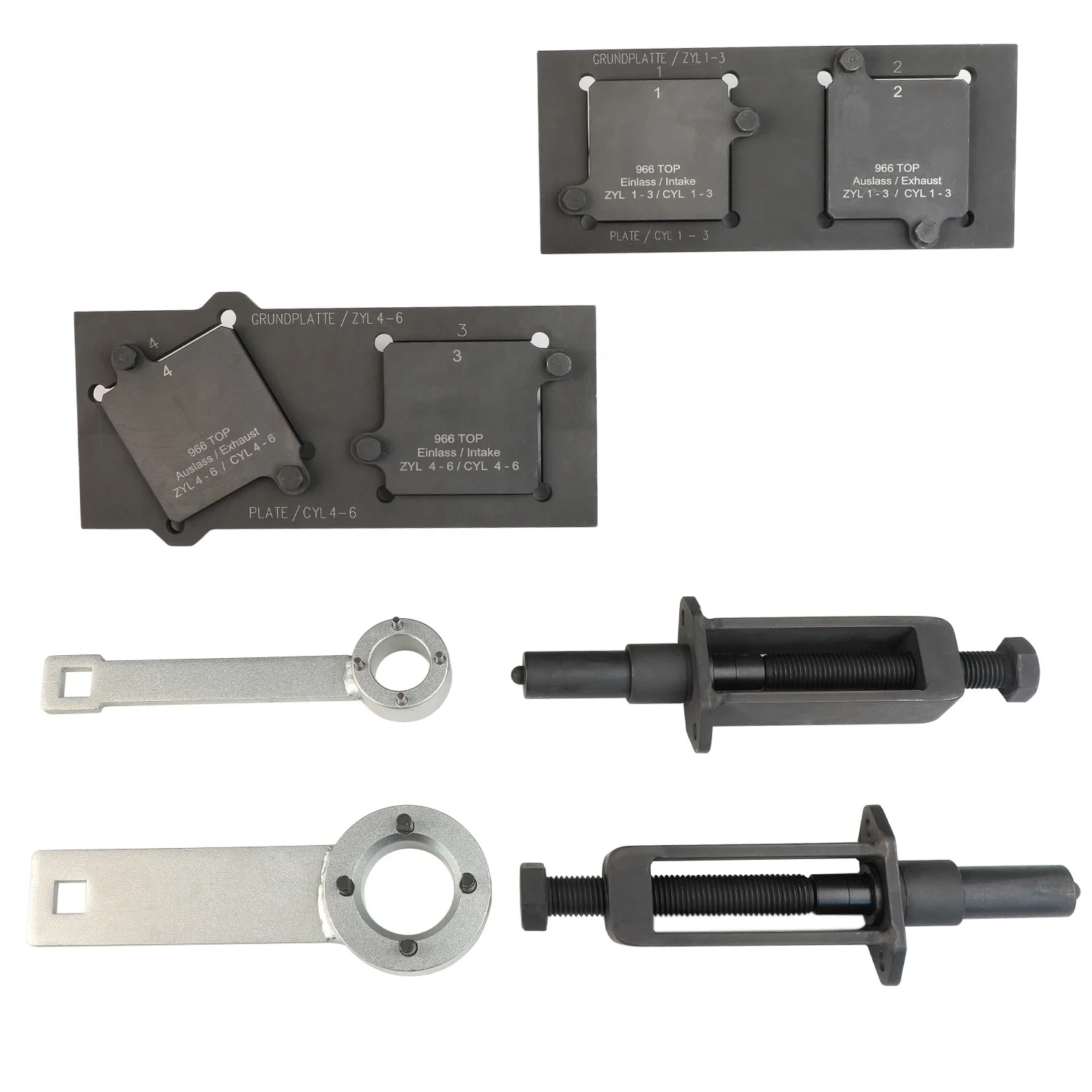

With a variety of products that covers everything from engine timing tools to braking systems and more HTL Hongtu provides solutions to meet your auto repairs We're committed to offering the right tool for each task whether you're a professional mechanic of a extractor bearing

HTL Hongtu values its customers We're extractor bearing to providing excellent support for our customers ensuring that you experience a smooth and positive experience from selecting the best product to receiving your order and beyond We provide quick courteous and professional support whenever you require it

Since 2013 HTL Hongtu has been an industry leader in the manufacture of automotive tools It is trusted by professionals and DIY enthusiasts across the globe Our tools are utilized by extractor bearing mechanics and people in more than 40 countries across the globe This global reach reflects our commitment to delivering superior quality and reliability that mechanics across the globe trust

Our extractor bearing are designed with meticulous attention to detail by expert technicians and engineers From our stringent quality control to our selection of the finest materials every tool is designed to last We're committed to providing tools that can tackle the toughest jobs and provide accurate results